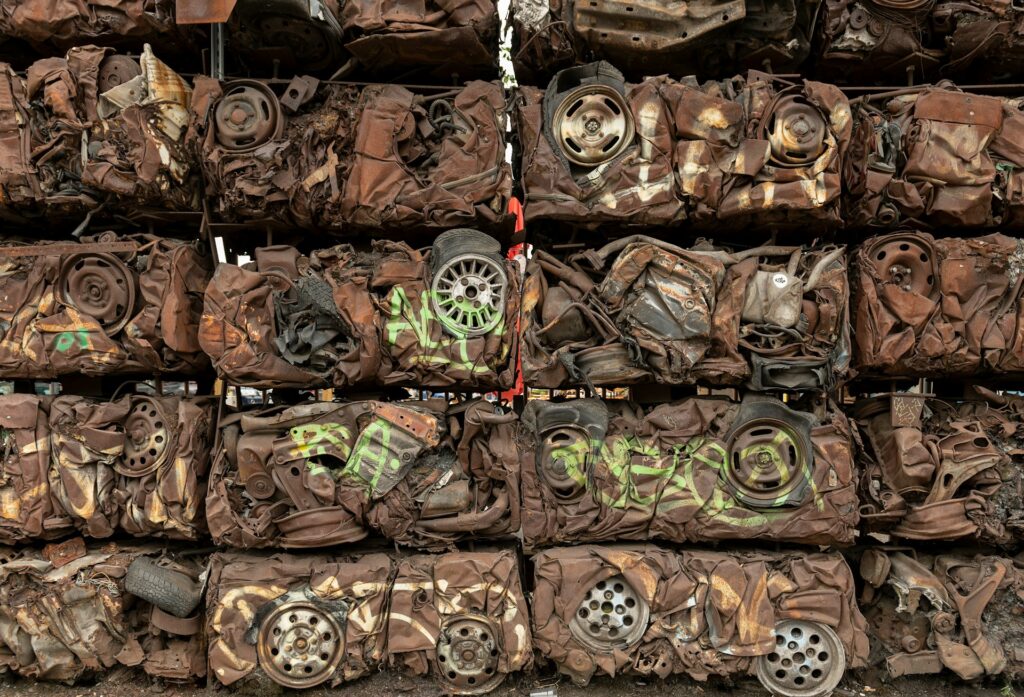

The recycling of scrap metal is vital to sustainability. It helps reduce the need for mining and lowers environmental pollution by reusing existing materials. There’s more to it than merely collecting discarded metal; it’s about transforming waste into valuable resources. The process is complex and includes steps like collection, sorting, processing, and manufacturing new products from recycled materials. For those interested in specific initiatives, services like refrigerator recycling Sussex County NJ demonstrate how specialized recycling can be integrated into broader operations. The objective is to establish a circular economy that continuously reuses materials while cutting waste and conserving natural resources.

Why Scrap Metal Recycling Matters

Scrap metal recycling plays a significant role in conserving natural resources and reducing greenhouse gas emissions. By recycling metals, we can reduce the need for mining, which is often destructive to the environment and consumes a lot of energy. It saves energy compared to producing new metal from ores. Beyond energy savings, recycling helps manage waste and reduce manufacturing processes’ environmental footprint. It also helps tackle climate change by significantly reducing carbon emissions associated with the manufacturing process of metals.

Types of Scrap Metals

Comprehending the distinct categories of scrap metals is vital for anybody aspiring to venture into the recycling industry. Typical classifications include non-ferrous metals like brass, copper, and aluminum and ferrous metals like iron and steel. Ferrous metals are magnetic and generally less valuable than non-ferrous metals, which are non-magnetic and often more corrosion-resistant. Non-ferrous metals, for instance, are usually more helpful and can be recycled multiple times without degrading their properties, making them particularly lucrative for recycling businesses. Each type has its own market value and recycling process. Understanding the distinctions will help you optimize revenue and ensure you are prepared to manage the recycling procedures needed for each kind.

Setting Up Your Sustainable Scrap Metal Business

Starting a scrap metal business requires obtaining licenses, securing a location, investing in equipment, and building relationships with suppliers and buyers. Following regulations and sustainable practices will set your business apart. Secure a site with adequate space for sorting, processing, and storing scrap metal, ensuring compliance with local zoning and environmental laws. Network with other recycling businesses, such as manufacturers and construction companies, to source scrap materials and find buyers. Staying updated on market trends and industry regulations can provide a competitive edge.

Tools and Equipment Needed

Successful scrap metal recycling operations require various tools and equipment, including weighing scales, shears, magnets, and vehicles. Investing in modern, energy-efficient equipment can improve sustainability and efficiency. Advanced sorting machines enhance metal separation accuracy, and providing safety gear for employees is crucial for a safe working environment. Upgrading to energy-efficient machinery saves costs and minimizes the carbon footprint, making the business more environmentally friendly.

Eco-Friendly Practices

Integrating eco-friendly practices is vital. This entails making sure non-recyclable wastes are disposed of properly and, whenever feasible, utilizing renewable energy sources. Educating your workforce on sustainable practices is another critical factor. The United Nations highlights that responsible consumption and production are essential for sustainable development. A zero-waste policy can further solidify your business’s environmental commitment. This means striving to recycle all collected materials and finding innovative ways to repurpose items that can’t be traditionally recycled. Adopting eco-friendly practices like rainwater harvesting, solar power, and waste-to-energy solutions can further enhance your commitment to sustainability.

Potential Challenges and How to Overcome Them

Like any business, scrap metal recycling comes with its challenges. Fluctuations in metal prices, regulatory compliance, and competition are common issues. Several factors, including supply and demand shifts, worldwide events, and economic situations, can cause significant volatility in metal prices. Research and networking can help you stay informed and navigate these challenges successfully. Observing market developments and being a member of trade associations can yield insightful information and beneficial relationships. Developing a flexible business model that adapts to market changes and exploring niche markets can also mitigate some risks. Establishing a solid reputation for dependability and quality can aid in obtaining long-term agreements and a consistent supply of scrap material, offering stability in a market that might otherwise be unstable.